Wow, it's the future, it's amazing!…

The musicians who visit the Syos workshop are always impressed by the technology used to craft our mouthpieces. But how does 3D printing work? What are the advantages and disadvantages of this method? Here's a whistle-stop tour of the world of 3D printing.

Additive manufacturing

Additive manufacturing is the official name for 3D printing. Unlike machining, which consists of starting with a block of material and chipping away until you reach the desired shape, additive manufacturing starts with nothing and the material is added and agglomerated little by little until the object is complete.

The different technologies

There are different additive manufacturing technologies, the most common are:

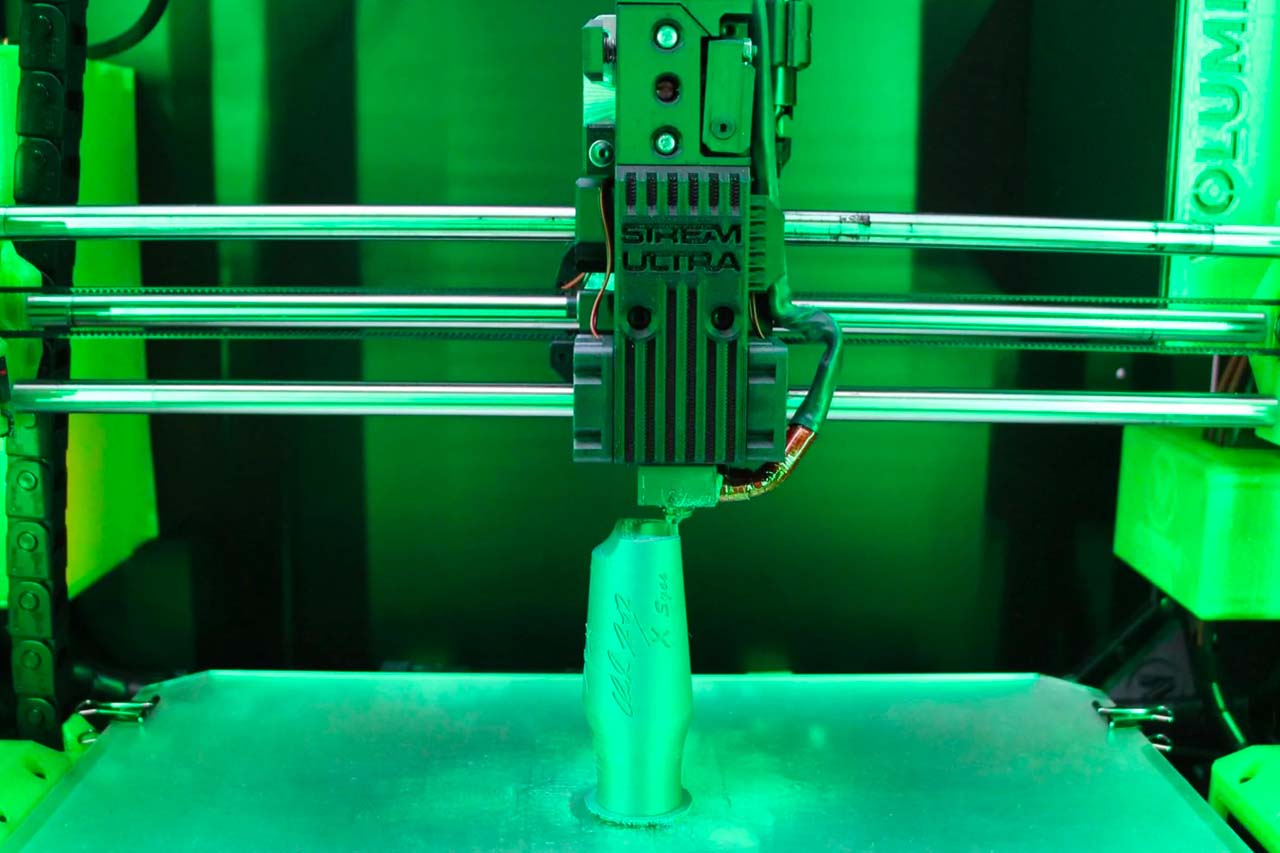

Fused deposition modelling:

A coil of material (called "filament") is heated to its melting temperature through a nozzle and is then deposited in very thin layers. The position of the nozzle varies over 3 axes (x, y, z) over time, which allows us to build the desired object layer by layer.

Selective Laser Sintering:

The object is built by agglomerating a powder of the chosen material (nylon, metal). A roller deposits a layer of powder on the manufacturing area, then a laser heats the powder to glue the grains together and solidify material. The operation is repeated until the entire object is built.

Stereolithography

The raw material, in liquid form, is polymerized layer by layer by UV rays that harden the resin in places. There are several forms of stereolithography: in some cases the object emerges from a layer of raw material (see the image below), in other cases the object is build in a tank of liquid from top to bottom.

Use of 3D printing for instrument making

The use of 3D printing to make musical instruments has increased over the last few years. For strings and percussion, the material used to make the instrument is crucial, because it vibrates and creates sound. For wind instruments, however, the material has no influence on the sound, it is the internal geometry that counts. We can therefore use 3D printing to create wind instruments with various geometric shapes, and all this in new materials. Here are some examples of 3D printing for making instruments:

The 3Dvarius

The 3Dvarius is an electric violin printed in 3D by stereolithography (thus by curing a polymer resin). It was created by Laurent Bernadac, engineer and jazz violinist. For a purely electric instrument, the choice of material is less important (compared to a traditional violin). The instrument has been optimized for comfort, weight and handling to be superior to standard electric violins.

J. Wiss's trumpet

French luthier Jérôme Wiss used 3D printing to work on a trumpet with a revolutionary form, without the flaws of standard trumpets (for which some notes are naturally out-of-tune). 3D printing was used to make and test prototypes, the final shape was made of metal.

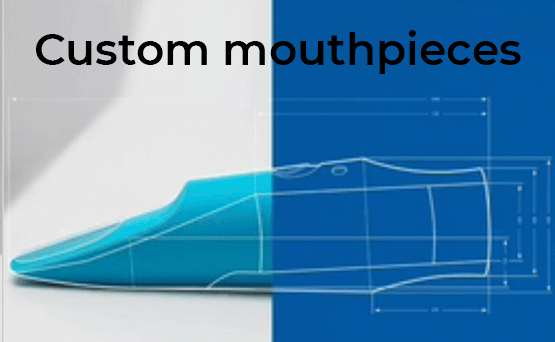

Syos mouthpieces

A unique mouthpiece for each musician, a saxophonist's dream, Syos made it come true! Syos mouthpieces are manufactured using fused deposition modeling. The geometry of the mouthpiece (the baffle, the chamber, the tip opening, the facing length...) are determined with the specifications of each musician. Thanks to 3D printing, it's possible to make unique pieces with different geometries for each musician (molding and machining cost less per piece, but only allows large series of identical pieces).

Read also: How is a custom saxophone mouthpiece even possible?

With 3D printing it's also possible to craft geometries that would not be possible otherwise: for example the deflectors used on certain baffles to create turbulence in the air flow. Last but not least, it's also an opportunity to design creative extra features printed into exterior of the mouthpieces (engravings, signatures ...).

Read also: Syos jobs: the 3D designer

Advantages and disadvantages

As a conclusion, here is a table summarizing the advantages and disadvantages of 3D printing technology for saxophone mouthpieces:

| Advantages | Disadvantages |

| - Makes custom pieces possible - Enables us to create new geometry - Very precise control of the geometry (1/100th of a mm precision) - Extensive design possibilities |

- Long (between 5 and 10 hours for a mouthpiece) - More expensive than standard techniques - Limited choice of materials and technologies (to meet the requirements of non-toxicity, color, solidity…) - Requires strong expertise |